Electrifying Progress

After moving back into SLO for a virtual Fall Quarter, I was able to resume work on the bike. First order of business: the battery. Unfortunately, after testing several of the salvaged batteries in the 18650 pack, I determined a new battery was needed.

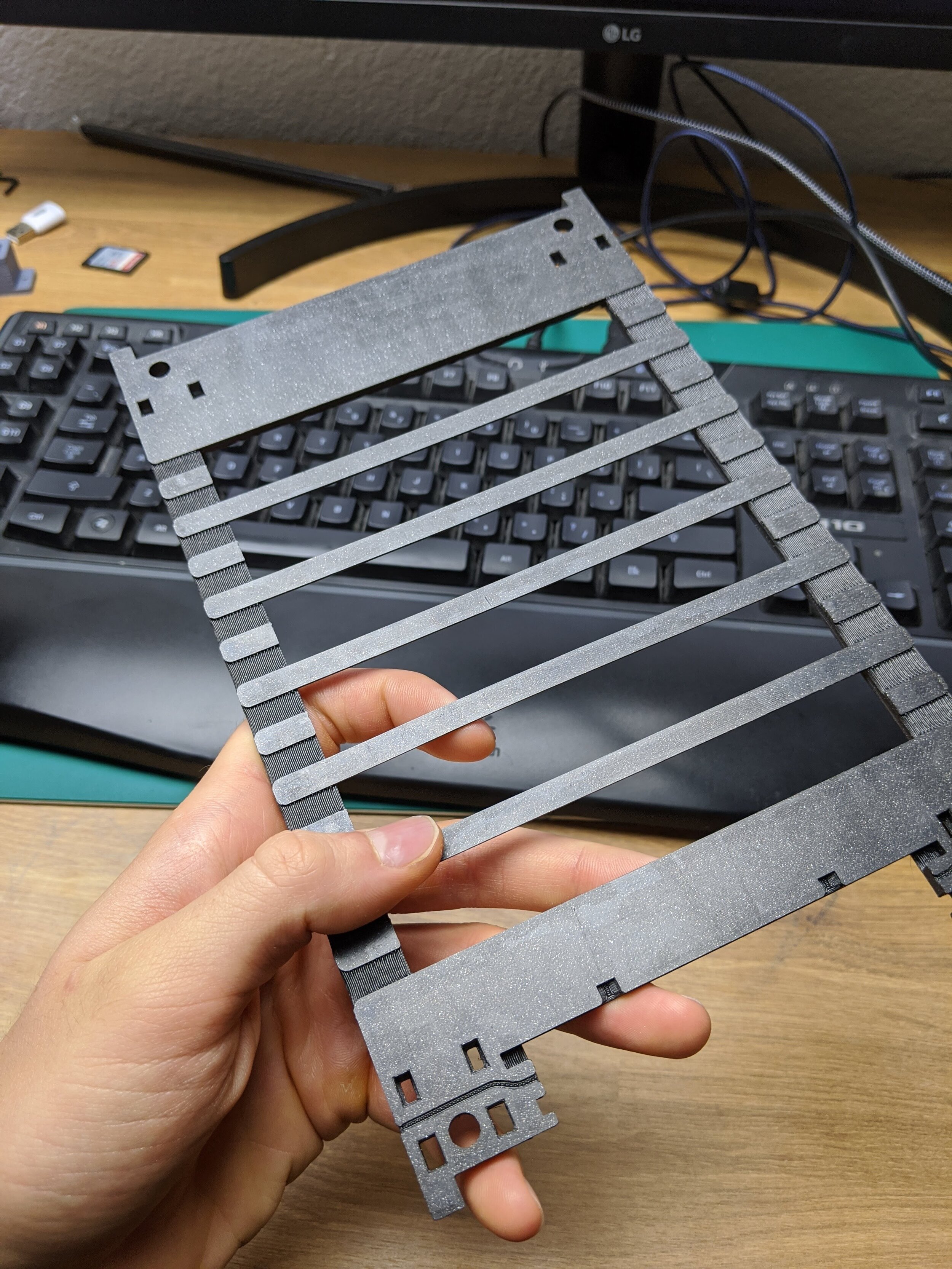

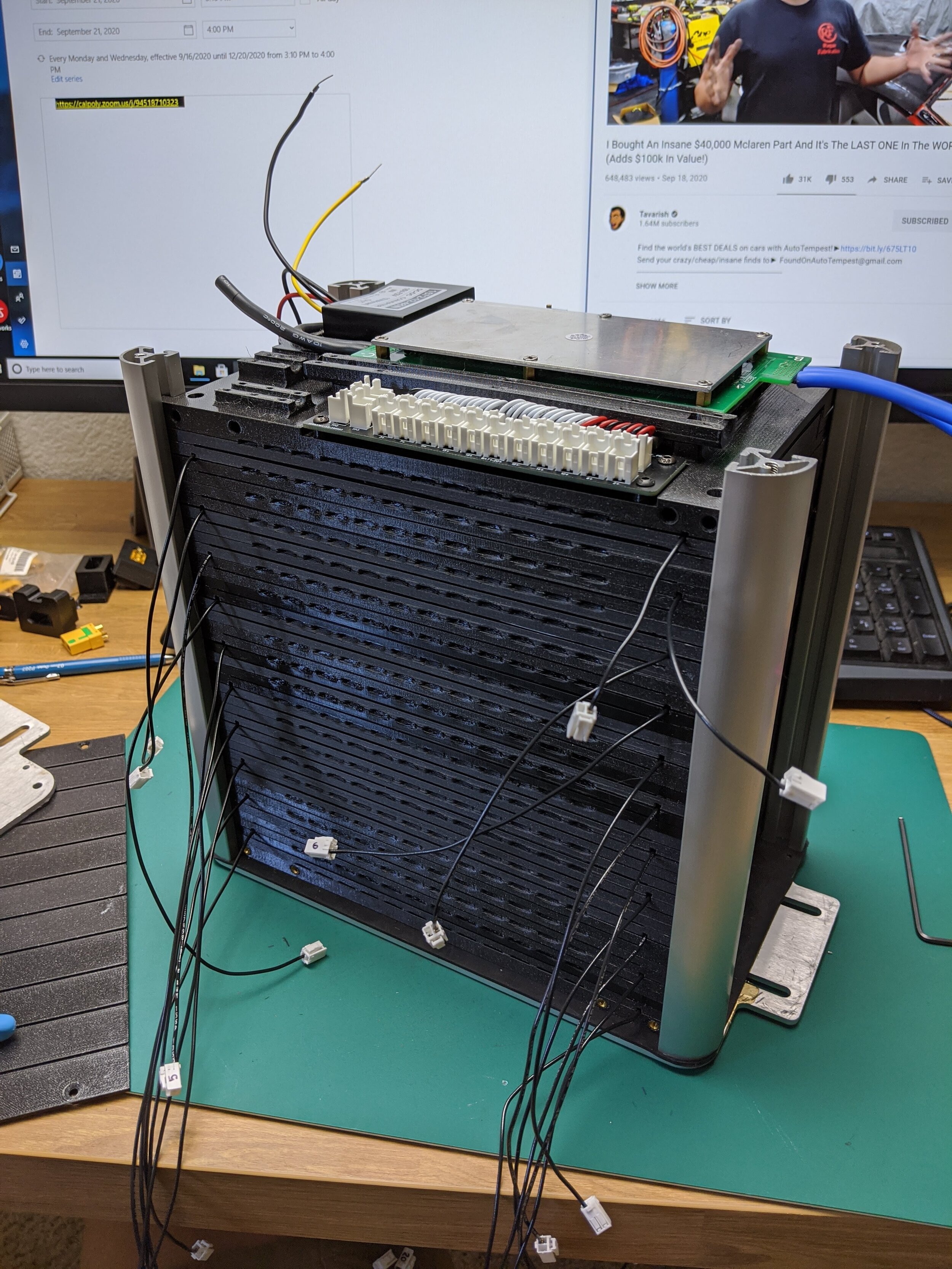

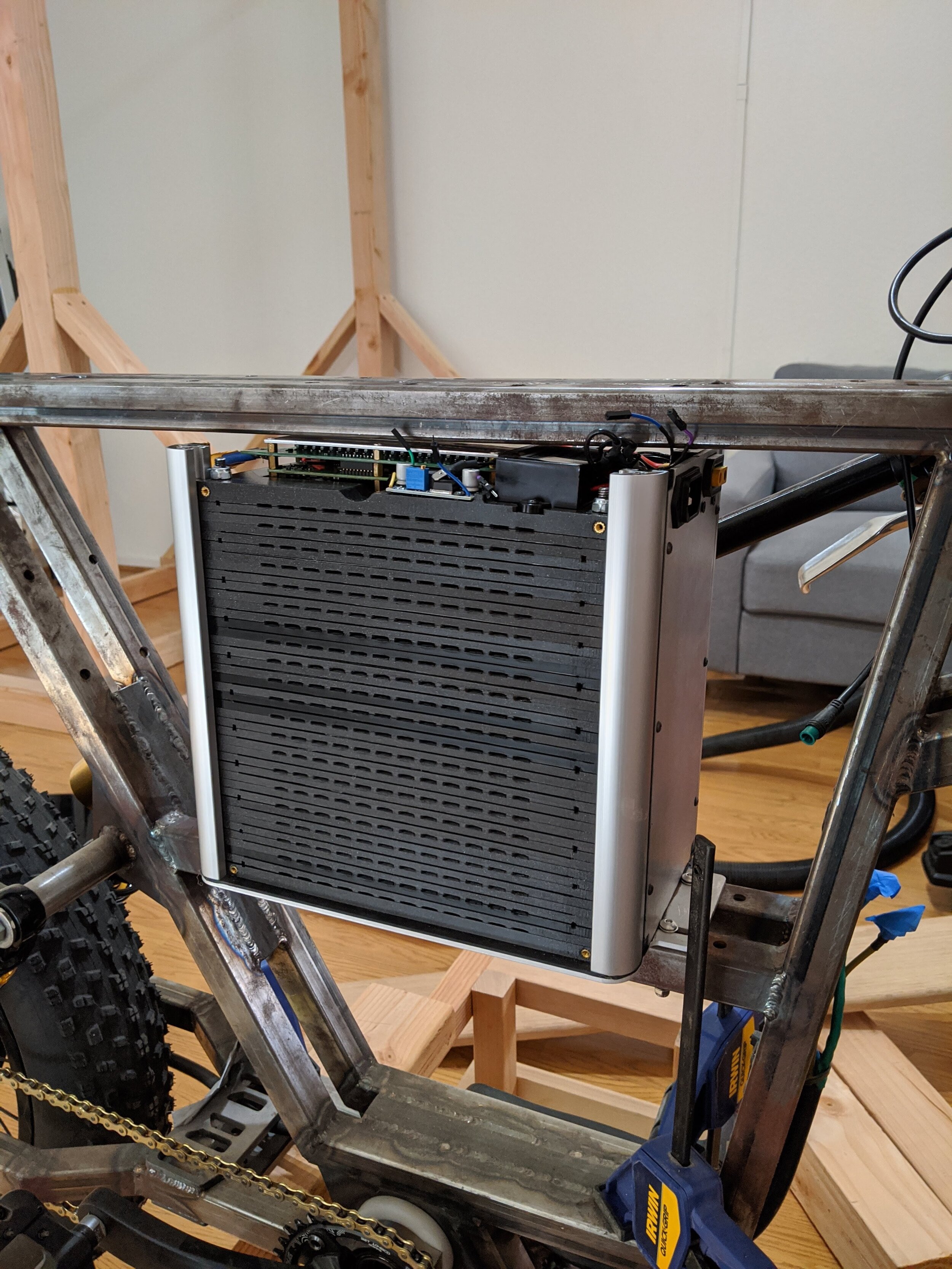

I designed the new battery to be enclosed in an insulated aluminum housing and bolt straight into the bike’s frame. For the cells, I used 20x salvaged pouch cells from retired Chinese electric buses. I designed each 3D-printed cell holder to support a copper/aluminum bus bar and slot into an aluminum extrusion frame system.

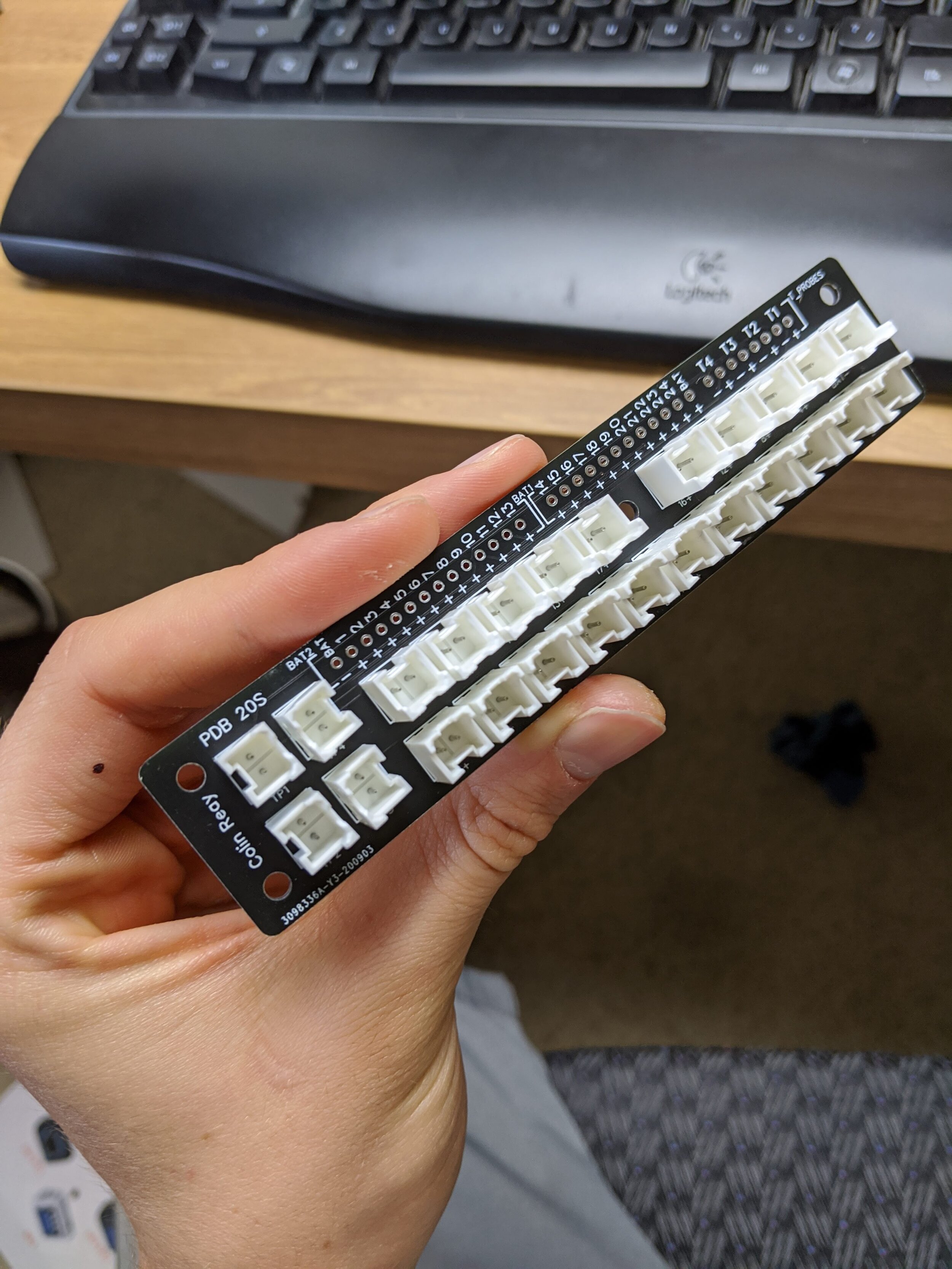

The battery is fully modular, with each cell and sense wire connection made by screw. This reduces the change of loose connections due to vibrations. The battery enclosure uses Butyl rubber as a vibration and electric isolator. I also made a custom power distribution PCB for simplified wire routing (both for sense wires and thermistors). The BMS monitors 4 different cell tabs and has built-in temperature protection. The battery has an internal step-down regulator and port for powering standard 12V components.