Designing the Wheel Truing Stand

I intend to build my cargo bike in the long john style; these bikes have a small (usually 20”) front wheel and larger (26” or similar) rear wheel. I want to be able to carry large loads with the bike and am planning on installing a front hydraulic or mechanical disc brake.

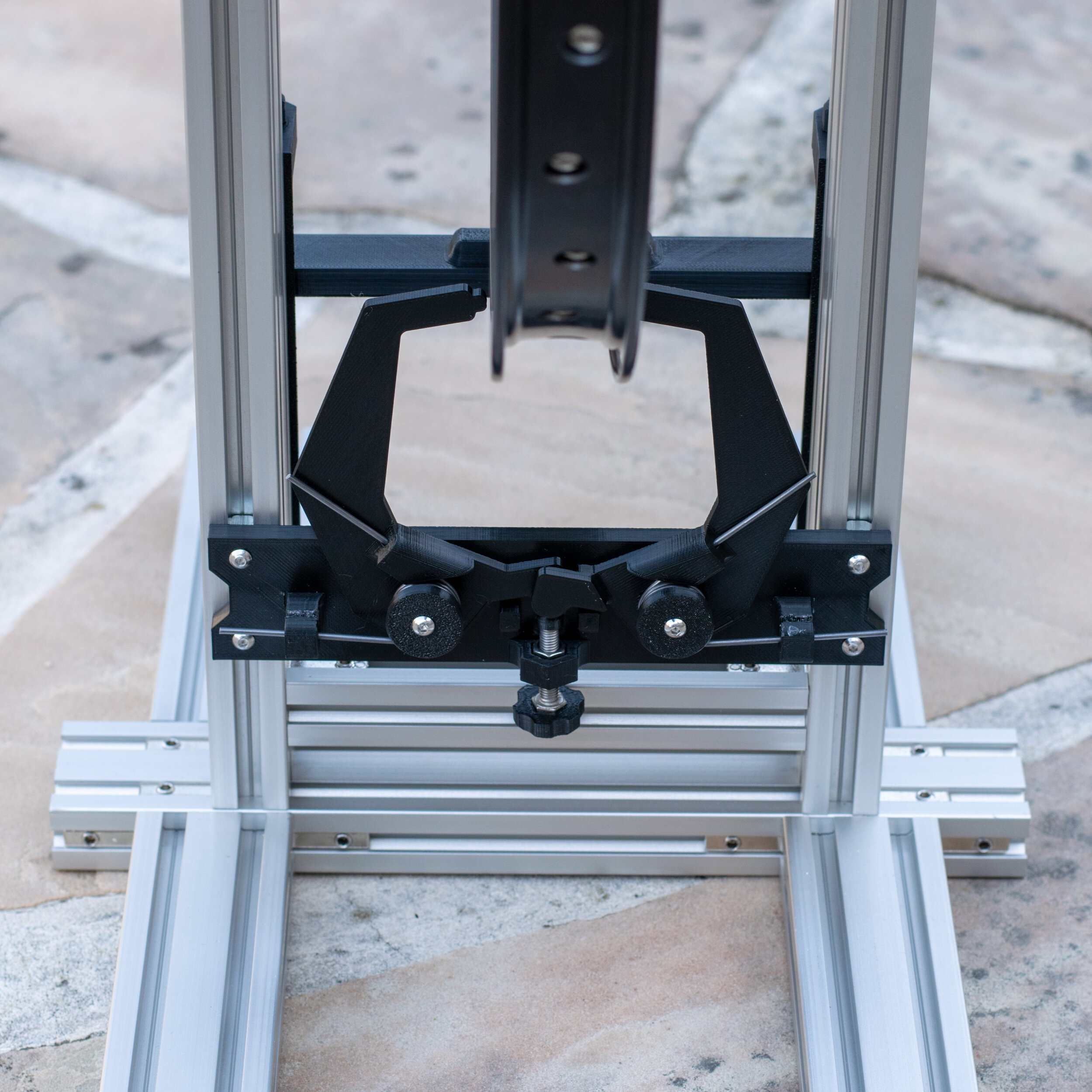

20” front wheels with a centerlock or 6-bolt disc pattern are quite uncommon - the only wheels I could find were extremely expensive and intended for BMX racing. Thus, I decided to build my own wheel and wheel truing stand. Some form of wheel truing device is necessary to build a good wheel, so I designed and built a wheel truing stand with about $45 of aluminum extrusion, torsional springs, fasteners, and 3D printed parts.

The bike hub attaches to the wheel stand with 4 thumbscrews for a secure fit. The truing stand has two calipers that are moved by an embedded M5 screw. These calipers open and close symmetrically, which allows you to simultaneously adjust for dish and side-side play in the wheel. There is a leadscrew driven bar opposite to the calipers which is moved up and down and measures wheel hop.

With the stand, I was able to build a 20” disc ready wheel with relative ease. I plan to build a 26” disc ready rear wheel if I cannot source one for a reasonable price.